Leveraging flexibilities for the European power system

The OSMOSE project aims to identify and develop the optimal mix of flexibilities for the European power system to enable the Energy Transition.

Four large-scale demonstrators led by Transmission System Operators explore the technical and economic feasibility of innovative flexibility services and providers, including: grid forming, multi-services by hybrid storage, near real-time cross border exchanges, and smart zonal energy management system.

Read the Final Project Brochure: Executive Summary and Full Version, available here.

OSMOSE is a four-year project started in 2018 and funded under the H2020 call LCE-04-2017 – Demonstration of system integration with smart transmission grid and storage technologies with increasing share of renewables

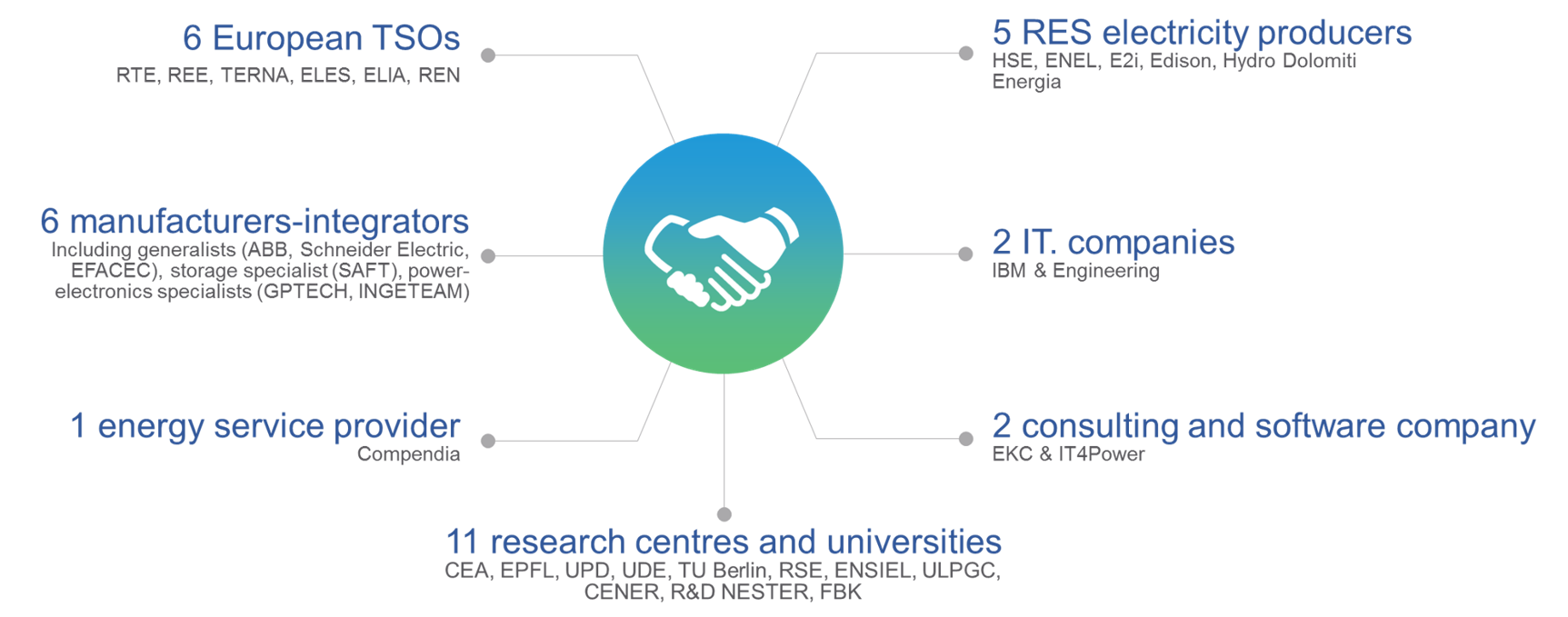

The OSMOSE consortium is led by RTE and is composed of 33 partners:

Recent news

Presentations of the Final Conference available

You will find below the presentations of the project Final Conference, 24 March 2022. OSMOSE_Conference_introduction OSMOSE_Conference_Session1_modelling and quantifying future flexibility Optimal mix of flexibility in long-term scenarios (Jens Weibezahn, TUB) …Read more

Read the OSMOSE Final Brochure: Executive Summary and Full version

Dear OSMOSE Community, We are delighted to announce that the OSMOSE Final Brochure in its two versions: the Executive Summary and the Full version are now available on our website …Read more

OSMOSE Final Webinar Series: Registration is open for 3 webinars hosted by RTE

We are delighted to inform you that 3 webinars will be hosted by RTE whithin the OSMOSE Final Webinar Series taking place from the 5th of April until the 4th …Read more

OSMOSE will participate in ENTSOE-E’s Innovation Friday on the 11th of March!

Osmose will be participating in ENTSO-E’s Innovation Friday workshop. This event is an opportunity for all the TSOs represented in ENTSO-E’s Research, Development & Innovation Committee to present their topics and developments in their projects. Represented …Read more

Next events

- No event